Plastic has now become an integral part of our life. These days,

we're surrounded by plastics. This material has found its way to every part of

our life. From household items to research equipment, everywhere you see,

wherever you go, everything you use, you can find a hint of plastic in it. Now,

the quality of the plastic may differ from one to the other but it is has

become an essential part of the life of human being. Despite the threats it

possesses to the environment, it hasn't affected its manufacturing in any way.

More and more people are into moulding plastic, and it has been a promising

business over the years.

A little history of moulding

The moulding of plastics is not something new and has been used

for making different plastic product since 1851. The process of heating and

melting plastics so that it can be moulded to different shapes and objects is

the primary reason behind plastic moulding. Though the process remains the

same, the mechanism that is used for moulding these plastics has gone under

abrupt change. During World War II, there was a massive demand for plastic

medical equipment is the reason behind its uprising.

The scenario of plastic moulding

in today’s world

Form carry bags to life-saving devices; plastic now plays a vital

role in the life of human being. With the help of computers and thanks to the

environmentalist who have showcased the threat plastic processes to the

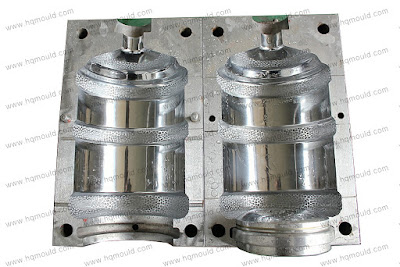

environment, these plastic moulding manufacturers, such as http://www.hqmould.com/ are recycling plastics and moulding them into different products.

This process not only saves costs but also protect the environment. The china mould manufacturer has developed new techniques which can be used to mould plastics

in a more efficient way which saves costs as well as lowers the threat it possesses

towards the environment.