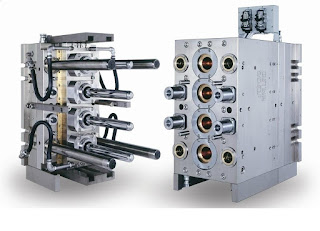

The process of shaping raw materials into various

forms by using the rigid form or model is known as moulding. Mould makers or

manufacturers make various kinds of machines to cater various industries. One such

industry includes the automobile where the mould maker offers high quality

moulding machines to facilitate automotive parts moulding.

When it comes to injection mould machines, China is the largest manufacturer in

the world. It makes the machines in huge quantities and by using advanced

technology which reduces the cost of production. The manufacturer uses high

quality raw materials and improved technology to come up with the best moulds.

Customized auto

parts

It is true that plastic mould industry has been there

for long. The mould industry is contributing a lot to the development of major

industry including automobile industry. Auto parts can now be made with the

moulding machines which bring down the cost of manufacturing the automobile and

also save a lot of time. More and more automobile manufacturers are considering

the use of plastic parts to save money and to produce lightweight automobiles.

It saves a lot of labour cost, energy and natural resources. The chief reason

for its popularity is that plastic products can be shaped in desired forms. The

mould machine helps in the production of high quality moulds and that too in

the least possible time. Companies can put forward their demands and get

customized auto parts moulds.

If you are looking for auto parts mould

manufacturer, you can check out the website of HQMOLUD. It is the reliable name in the realm of

automotive parts moulding and mould making.