China

traditionally had a bad name linked to Quality but recent years have seen a

major turnaround in Chinese product quality. So what difference does this have

on the plastic injection molding units? Well with the increasing demand for plastic

items being used globally and those plastic items being too bulky to ship

across the globe so more companies are setting up the units in their country.

They then import the pre-forms from China and simply inflate them to make the

plastic items. This may seem absurd but this still results in manufacturing

plastic items much cheaper than any other nation globally thus making China the

main supplier of the plastic mould globally.

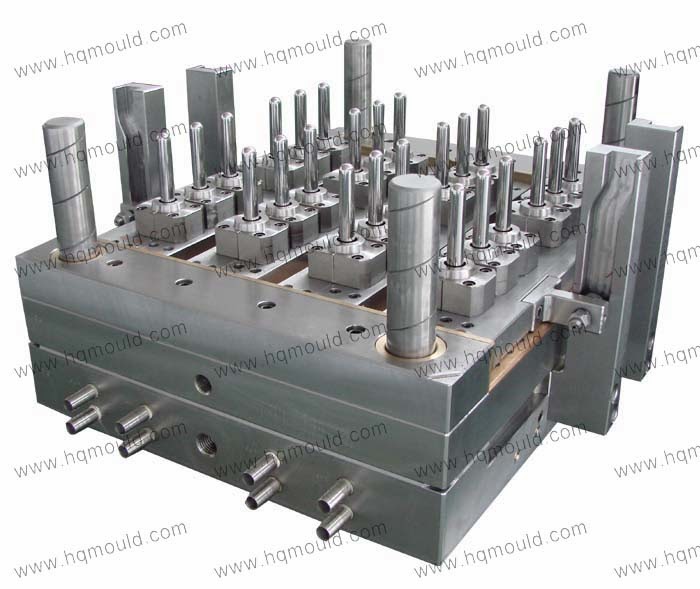

Most of the moulding machine made in china is

versatile meaning they can used to make many different products. This is a very

important aspect linked to the moulding machines since they don’t limit you to

one product and you can seek many different orders without investing in

different machines. Most machines are also highly sophisticated with digital

technology used to run the machines. It’s vital to make sure every aspect linked

machines is understood thus allowing you to make the right choices.

With projections showing the packaging industry in

growing at an alarming rate it’s critical to do your math’s rightly thus

ensuring you get every aspect linked to the services in the right manner. The

china made machines may be the cheapest and best but you still need to conduct feasibility

studies to ensure you get the best services.

No comments:

Post a Comment