If you

wish to make any furniture of plastic mould then you can do it with the help of

plastic moulding. Try to acquire some prior idea about

how it works. It is always believed that a better understanding of the matter

would help to finish any project rapidly. The concept of plastering came into

being during the 21st century, and use plastic products can be made out of the

same. It started since 1851 during the advent of human-mad

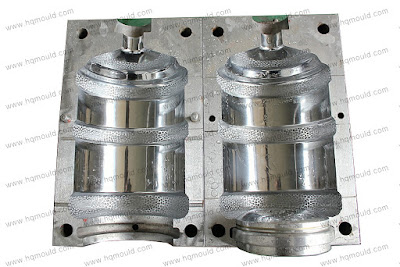

Process for moulding

To

accomplish the process, the plastic is heated, and then the molten material is

given the desired shape. Plastics have a wide range of importance when it comes

to using them for our household utensils. The plastic

mould manufacturer can recycle the material create

another new item out of the used product. With advancement in technology, the

plastic moulding industry has advanced a lot. Thus, plastic moulding is one of

the preferred methods which have some advantages as well.

Ø

The mould is designed according to the

requirement of the customer, and it is one of the quickest methods as compared

to other methods of moulding. The manufacturer can create more designs in less

time from a single mould. The moulding industry could be considered as an

effective one in terms of high production output.

Ø

While using the process of plastic

moulding, the manufacturer has the opportunity to use different varieties of

plastics. The process is undertaken with the help of co-injection moulding.

Ø

While using the plastic injection

moulding, the filler reduces the density of the plastic used and eventually

increases the strength of the product. For making parts of durable products,

the plastic moulding is the best option.

Ø

With the help of plastic moulding, the

manufacturer would get detailed designs as the moulds are subjected to

extremely high pressure.

Therefore,

according to the present scenario, the plastic moulding is a widely used

procedure and for more details visit http://www.hqmould.com/.

No comments:

Post a Comment