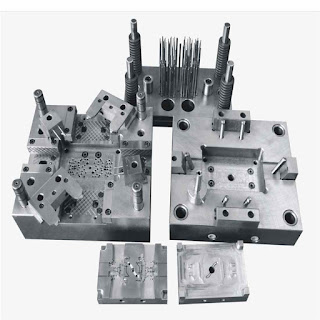

Automotive parts

moulding or car body moulding are

basically protective and decorative mouldings on the automotive parts or the

body of the car. The term generally applies to both the material and the detail.

Automobile parts moulding include lower body moulding, side body moulding,

window mouldings, mud flaps, footrest moulding and door mouldings. It is

important for automobile parts mouldings to be scratch resistant and weather

resistant. The gloss of these mouldings should be a perfect match to the body

and the different parts of the car. It would always be a good idea to go for

the mould manufacturing services of different companies that employ specialized

professionals for this job. There are companies throughout the world dealing in

the manufacture of best quality automotive moulds perfectly suited to the

requirements of different automotive manufacturers.

Depending on the Mould Manufacturing Companies

There are a

large number of automotive parts moulding manufacturers and suppliers throughout

China. These companies are very popular for their supply of top quality and

performance based automotive mouldings. In most companies, auto moulding is one

of the most important series of plastic mould based on manufacture and design

of automobile gages, dies, welding and assembly fixtures. There are many mould

manufacturing companies in China that offer the domestic and international

customers mould manufacturing and development services for Ford, GM,

Mercedes-Benz, Fiat, Audi, BMW, Renault, Volvo, Land Rover, Peugeot and many

more internationally well-known automotive mould groups. There is always that

perfect mould available for almost any vehicle brand. For more information,

you may look up at HQMOULD.