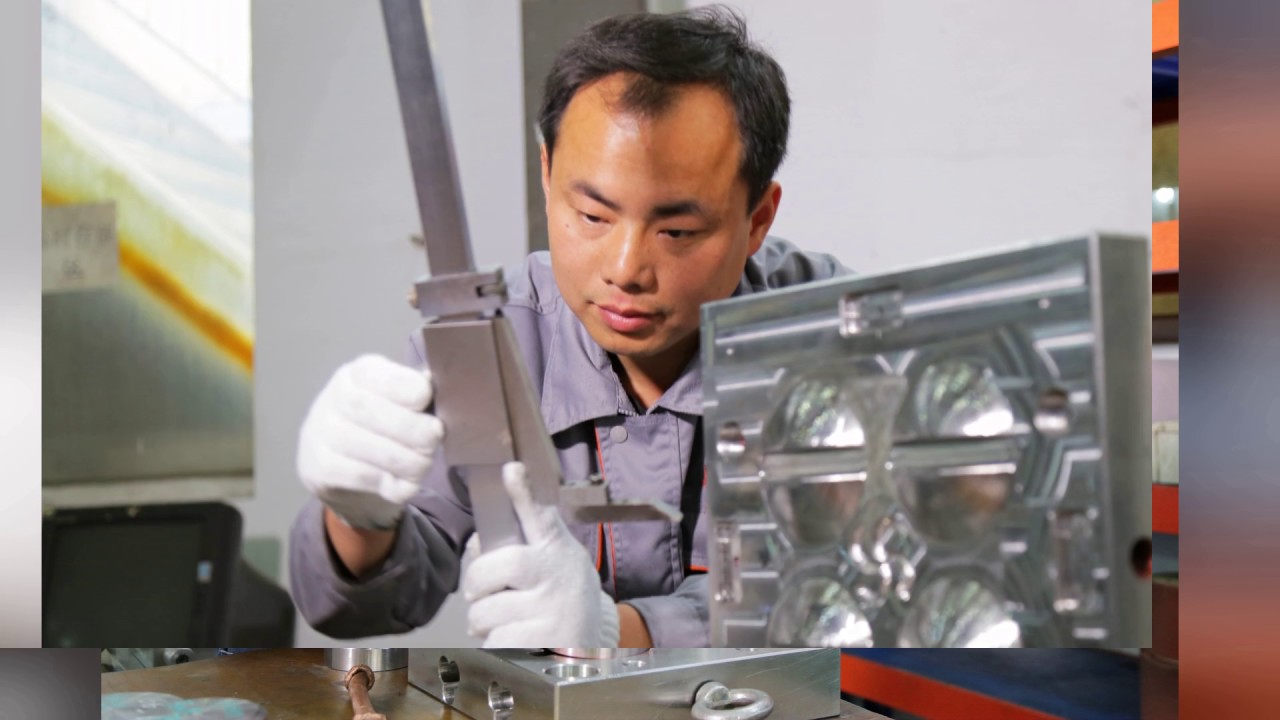

Moulding

is one of the rapidly growing and fastest industries in the world today. The moulding industry is huge and it has different

types which are necessary for different industries. But amongst all the automotive parts moulding is one of the major

players in this segment. Now let’s learn about various types of moulding that are drastically used to create

various kinds of products.

Different types of moulding

- Automotive Parts Moulding: this is used to create various exterior and interior parts of a car for protection and decoration of the vehicle. Footrest moulding and door moulding are some of the examples of this kind of job.

- Plastic moulding: blow moulding machine is generally used to create various products with the help of the plastic as a material. This is widely used today to create different kinds of products like chairs, crates and so on.

- Injection moulding: with this method of moulding using the thermosetting plastic materials and thermoplastic different kinds of products are created.

- Injection Moulding Machines: with the help of a machine which is known as presses plastic moulds are turned in to various products and components.

- Extrusion moulding: with this process, you can create hoses, straws for drinking, curtain tracks, and pipes and so on. In order to create a long tube like products, this moulding process is generally used.

- Rotational moulding: where you have to create hollow plastic products there you have to employ this moulding technique. It is a very cost effective process and also wastage is very minimal too.

- OEM moulding: it stands for the original equipment manufacturer moulding process. With this process, you can create a unique and particular product as per your requirement.

So if

you are looking for top quality moulding

machines then you can get in touch with http://hqmould.blogspot.in/2017/07/why-you-should-be-careful-while.html. They

are one of the biggest and top suppliers of quality moulding machines.