Sitting on those chairs

and tables might never have made us think of how they are made. But when we

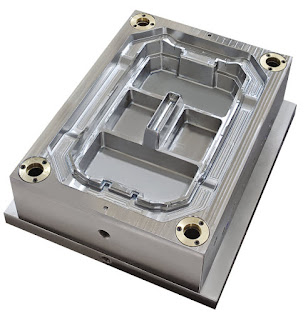

come across the plastic mould making company in China. We think of the

creativity and the hard work behind these plastic products.

Their

products:-

Other than that, they

are also the manufacturers of plastic mould equipment for mould factories. Most

popular with commodity moulds,

they are also serving with sheet metal moulds, milling machines surface

grinders and line cutting with various speeds. These are just the initial

components. The company also expertise in making bench drills chamfering machines,

hardness testers and tapping machines.

Building

strategy:-

To build these moulds

is not as easy as it is. Making this needs a strategy to be designed and that

is to be maintained properly. A proper step is needed to be followed for a

better mould building.

·

For making these moulds, they specialize

in plastic injection moulding equipment, which is needed to inject the molten

material into the mould.

·

Later it is given on to cooling and

solidifying the exact shape and structure required. This kind of injection

technology is not just a prevalent step in thermoplasty and thermo setting.

·

But is also for glass, metal

confectionary and elastomers. They consider this with accordance to their

clients.

·

First they would consult their client. After

that, they are going to study the requirement in a proper manner.

Further they

focus on every single part of it with closely delivering the finest of the

mould to their client. To know more on commodity moulds visit us at :- HQMould

No comments:

Post a Comment